15

11

Smallhomeappliances

682 Views

Panasonic's "Establishment of a Recycling Supply Chain for Home Appliance Recycled Resin" Receives the Minister of Economy, Trade and Industry Award at the "2021 Commendation for Resource Recycling Technologies and Systems"

Panasonic Corporation (Panasonic) Appliances Company, Kitchen Space Division (*1), Appliances Company, Manufacturing Innovation Division, Kato Resin Recycling Plant (*2), Panasonic Manufacturing Innovation Division, Panasonic ET Solutions The company received the Minister of Economy, Trade and Industry Award at the 2021 Awards for Resource Recycling Technologies and Systems sponsored by the Japan Environmental Management Association for Industry.

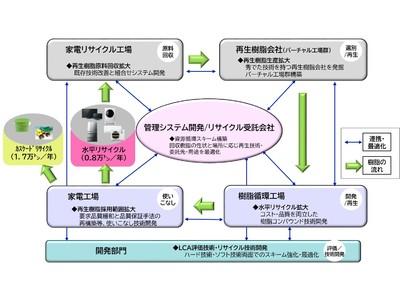

Air conditioners, televisions (cathode-ray tubes, liquid crystal, plasma), refrigerators/freezers, and washing There is an obligation to recycle parts from machines and clothes dryers. The resin used in home appliances is also recycled after being sorted and collected, but there are some materials that are discarded, such as resin containing glass fiber, which is difficult to separate. In addition, the use of recycled resin is limited due to the difficulty of using it, such as the removal of peculiar odors and the recovery and control of physical properties. The award-winning project "Establishment of a Recycling Supply Chain for Home Appliance Recycled Resins" is a nationwide activity in which related departments of the Panasonic Group worked closely together and involved affiliated companies with the aim of resolving issues related to recycled resins. "Improvement of raw material recovery rate at home appliance recycling factories", "Development of new recycled resin that achieves both cost and quality", "Increased production volume at resin factories", "Expansion of usage at home appliance factories", and "Coordination of the whole" Scheme", we have built a nationwide recycling supply chain in which each department that plays a role in the right place cooperates with each other to rotate the life cycle of recycled resin. Through this initiative, we have advanced the sorting technology for resin raw materials, improved the quality of recycled resin, and evolved the technology to make full use of it. Through cascade recycling, 17,000 tons/year can be recycled for the same use as the original product. Horizontal recycling achieves resin resource circulation of 8,000 tons/year. In addition, we have optimized the scheme through life cycle assessments, achieving a reduction of 95,573 tons of CO2eq in greenhouse gases and a reduction in energy consumption of 1,337,299 GJ/year. Panasonic will further expand the use of recycled plastics by advancing individual technologies and by standardizing the entire scheme. We will also promote cooperation and sharing of know-how with related companies to contribute to the realization of a circular economy. [Role in the award-winning project] Kitchen Space Business Division, Appliances Company, Panasonic Corporation: Development of technology for using recycled resin and expansion of the range of use of recycled resin. Kato Resin Recycling Factory, Manufacturing Innovation Division, Appliances Company, Panasonic Corporation: Low cost and high cost Development of high-quality resin compounds ・Panasonic Corporation Manufacturing Innovation Division: Optimization of schemes through life cycle assessment ・Panasonic ET Solutions Co., Ltd.: Construction of overall schemes for recycling-oriented supply chains, as well as excellent domestic and overseas technologies Construction of a global virtual factory group through the discovery of recycled resin companies with 2 Awarded for the organization name at the time of application, renamed to the following from October 1, 2021 Environment Promotion Center, Business Process Innovation Division, Business Process Innovation Division, Lifestyle Business Division, Lifestyle Appliances Company, Panasonic Corporation- Press Release >

- Panasonic >

- Panasonic's "Establishment of a Recycling Supply Chain for Home Appliance Recycled Resin" Receives the Minister of Economy, Trade and Industry Award in the "FY2021 Commendation for Resource Recycling Technologies and Systems"